Fleet Overhaul Series, Part 6 of 6: Electronics and high-floor wheelchair lift repair

Fleet Overhaul Series, Part 6 of 6: Electronics and high-floor wheelchair lift repair

This is the final article in a six-part series about Fleet Overhaul, the vehicle maintenance centre down at Burnaby Transit Centre. (Check out the earlier articles on the body shop; panel fabrication; the paint shop; high-mileage vehicle work; and the warehouse.)

A little room just to the side of the body shop floor is where the electronic signage is repaired.

Overhaul manager Jeff Dow explained that they not only fix the signs, but also program them to flash custom messages like “Go Lions Go” or “Countdown 2 Gold,” which the buses showed for the Olympics.

There’s also an electric shop nearby, where electronic components of vehicles are repaired. Defrosters, fareboxes, new electronic motors, circuit boards, and more are taken care of here. (It’s a clean room, so we didn’t get to take an actual peek inside.)

Repairing wheelchair lifts for high-floor buses

Wheelchair lifts for high-floor buses are in fact a special challenge for Fleet Overhaul.

While lifts for low-floor buses are just small ramps that flip onto the sidewalk, the high-floor lift is a complicated beast that extends out from under the driver’s seat, then lowers itself down to meet a passenger in the wheelchair.

The high-floor lifts can be quite finicky, and if they’re not working, it’s often because of alignment of the unit—not necessarily because the lift isn’t functioning.

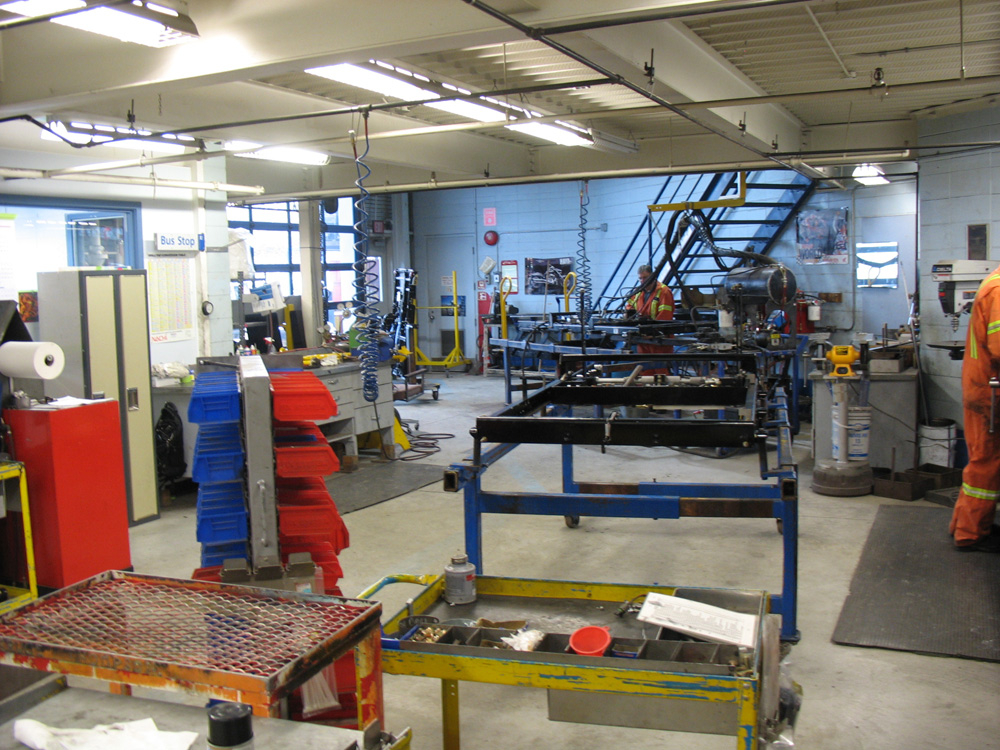

The lifts often show up at Fleet Overhaul for repair work, and a small area is set aside for those tasks.

Considering the warehouse setup at Fleet Overhaul, you might have guessed that Fleet Overhaul does build all the parts for the lift. There’s only one company in the U.S. that supplies the high-floor lift parts, and it’s much easier and cheaper for Fleet Overhaul to make the parts themselves.

So here is a video of a wheelchair lift being tested! (That’s overhaul manager Jeff Dow who steps in to explain a few things about the lift.)

And that’s it for the series on Fleet Overhaul! It has been quite some work putting all of this together and I sure hope you enjoyed it.

A big thanks to Jeff Dow and Jack McKenna for their patience and help with these articles. And of course, a big thanks to the hard working crew out at Fleet Overhaul!

I wonder if they’ve been able to fix the narrow text on the route signage on some of the 71xx and 72xx buses.

Cool stuff, I dont know why i never thought about translink as a job option once i finish my electronics work

can u plz plz! make a series on the skytrains?

Okay, I’ll look into it :)

Found this blog when searching for something else. Have put it in my bookmarks and will check back soon.

Is this where the fix the scroll type destination signs found on the older buses? Also why did the switch the colour of the destination signs from green to orange?

This is indeed where they fix the destination signs. I don’t think the colour switch was intended: it’s just whatever signage system comes with the buses.

Is this where the do all the electrical repairs on buses such as replacing burnt out fluorescent tubes for interior lights? Also are repairs such as replacing burnt out lights done on a regular basis or just during fleet overhaul?

If this is where they fix the destination signs, are the destination signs for community shuttles, highway coaches and the older Mylar film destination signs fixed here too?

If this is where they fix the Wheel chair lifts for high floor buses, where are wheel chair lifts for low floor buses, community shuttles and highway coaches fixed?

Ric, here’s the answers from fleet management:

Why are the Mylar signs typically repaired at the garage instead of fleet overhaul?

Why are the community shuttles not kept as long as the conventional and articulated buses?

If conventional and articulated buses are retired/scrapped after 18-20 years, how long are the community shuttles in service for before they are retired/scrapped?

On the other hand are the highway coaches kept for the same amount of time as conventional buses before they are retired/scrapped?

Ric, here are the answers from fleet management.

Why don’t they just rebuild the engines and transmissions for the community shuttles at fleet overhaul, like they do with the engines and transmissions on the conventional and articulated buses so that they can last a few more years before being scrapped?

Ric: here is the answer from fleet management.

I was on a bus this morning that had a Flip-dot destination sign, and I noticed something strange with the sign. The bus was running the 410 route, and this is what I noticed strange with the destination sign.

The back number sign that displays the route number showed 410 which was correct. However, the front and side destination signs both show different displays. The side sign showed 410 22nd St Station but the front destination sign showed 401 One Road.

What caused this to happen? Did the flip-dots on the front destination sign fail?

I did let the driver know about this problem and he told me that he was going to let to transit garage know so that they could perhaps send out a “road services” vehicle so they could try to fix it or perhaps doing a bus change.

[…] the way! The old high-floor ramps were notoriously temperamental and not useful once on the fritz: this post for […]

Ric: here is the answer from our fleet management department.

Here’s a question I never knew who to ask: what do the letters that appear on the rear route number sign stand for when the front signs display “not in service”? The rear sign always says CHK and then some other letters.

Eddie: it means “Check Message Writer.” Essentially it’s a default message that shows up when the front and side displays say “Not in Service.” There have been rumblings to program it with something that makes more sense but I haven’t seen any actual movement on that yet.