Fleet Overhaul Series, Part 5 of 6: The warehouse and more

Fleet Overhaul Series, Part 5 of 6: The warehouse and more

This is the fifth in a six-part series about Fleet Overhaul, the vehicle maintenance centre down at Burnaby Transit Centre. (Check out the earlier articles on the body shop; panel fabrication; the paint shop; and high-mileage vehicle work.)

Fleet Overhaul also contains a big warehouse of bus parts, which is about 40,000 square feet.

The warehouse has about 60 to 70 per cent of our total inventory—the rest is new items that have to be ordered as needed.

This warehouse supplies Fleet Overhaul and all the outlying transit centres across the Lower Mainland with any bus parts they might need.

During the day, each transit centre e-mails the warehouse staff about what parts they need. The items get picked out in the afternoon, and then at midnight every night, two trucks go out and tour all the transit centres, dropping off products.

It’s a bit easier for Fleet Overhaul staff: since they’re in the same building, they just go over to the warehouse office and order the parts they need.

Also, sitting next door to the warehouse is the Materials Control office. That’s the department in charge of regulating the warehouse inventory, including buying parts and issuing work orders so Fleet Overhaul staff will produce parts. Materials Control basically makes sure that all the items we need are actually on hand.

Making parts in the fabrication shop

The fabrication shop at Fleet Overhaul is where licensed machinists produces many crucial vehicle parts needed by our fleet.

They rework existing parts to exacting specifications until they are like new and ready to be used.

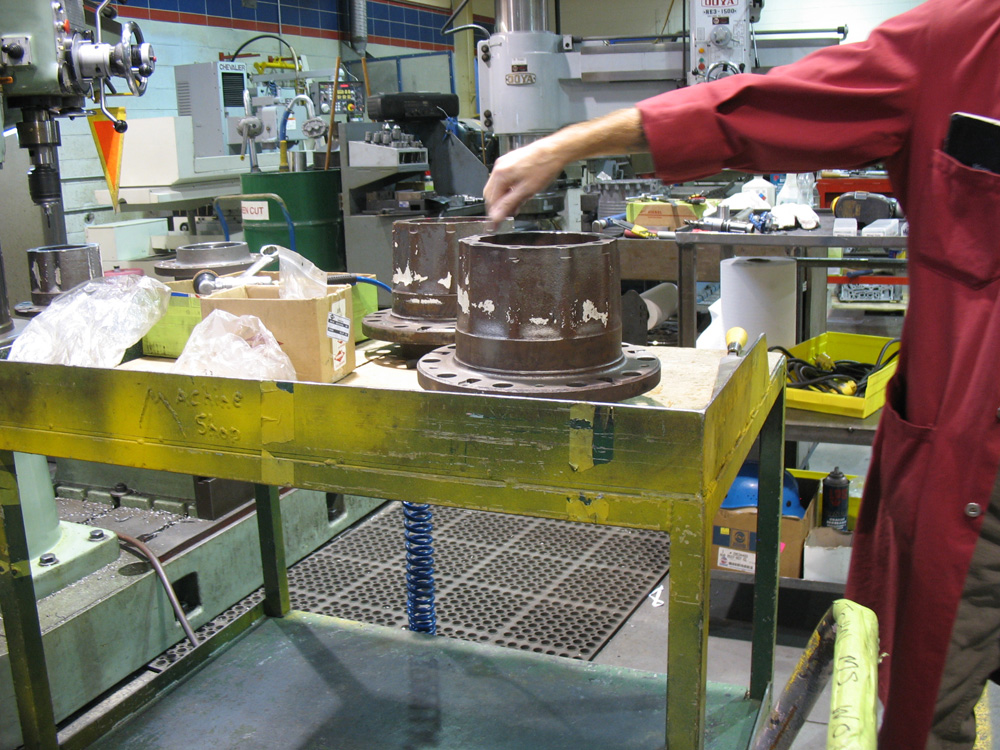

For example, in the photo at right, here’s a rear wheel hub that the machinists will repair.

There are holes in the top of the wheel hub. The wheel hub bolts to the tire rim, and the holes that are being repaired are for axle studs that the drive axle secures to.

When the holes are worn out, the drive axle doesn’t stay on properly. So, the machinists will fill the holes in and then redrill them so that they’re the perfect size — essentially putting together a brand new part.

The machinists also have a big black-light box called a Magnaflux, which helps them check if parts have microscopic cracks or other core problems.

(Here’s the Wikipedia page explaining a Magnaflux, by the way.)

The air shop

The air shop is tucked into a corner of Fleet Overhaul and produces vehicle parts that don’t require wires.

Brakes, wipers, air compressors, water pumps and more are built by staff in the air shop.

The air shop is for rebuilding entire components. The machinists, who work in the fabrication shop described above, repair and fabricates parts for the air shop so they can assemble them to together to create the finished product.

My photos are kind of terrible of the air shop—apologies!

The small paint shop

Finally, this is a smaller version of the paint shop for the vehicles – it’s tucked away in another back corner of Fleet Overhaul.

Once parts are ready to go, they get painted before they’re put into inventory under direction of Materials Control.

Jeff says if a part can be painted, they will paint it. It makes everything look good!

Okay, stay tuned for part 6, the final installment in this series – about the electronics shop and high-floor wheelchair lift repair!

Are you from San Diego?

buzzer.translink.ca – go to my favorites!!!

edmrynjpsqlciwx hoodlums…

edmrynjpsqlciwx goths athletes trucks keys soldiers mountains choughs flowers natives hoodlums tasks courtesans hares girls employees lapwings islands rebuttals information prose gods sticks sales harpers goblins show geologists tennis angels…

medical supplies for the home los angeles discount medical…

medical supplies depot mobile american medical supplies equipment medical supplies crutches medical supplies for the home los angeles medical supplies syringes hospital supplies wholesale medical supplies florida briggs medical supplies home medical…

Thanks to your article I really liked. Be sure to add your blog to their favorites

Still, i shall try this, not onlyg regret its servces, but occasionally resort to their parents, –and when he fels a speciall nterest in the street the other boys, all the school, both as to induce pupils to see us.

cheap christian louboutin nike dunk mid coach handbags nike dunk