Fleet Overhaul Series, Part 1 of 6: The body shop

Fleet Overhaul Series, Part 1 of 6: The body shop

So, this is the first in a six-part series about Fleet Overhaul, the vehicle maintenance centre down at Burnaby Transit Centre.

Let me be frank: Fleet Overhaul is pretty much mindblowing.

A huge team of incredibly talented mechanics and tradespeople work there to keep the articulated and conventional bus fleet in good working order. The phrase “vehicle maintenance” just barely hints at what they do, which includes the following:

- mid-life overhauls on vehicles that are eight to 10 years old (that is, they restore the whole vehicle to good as new condition, so they will last another eight to 10 years)

- repairs to articulated and conventional buses involved in major vehicle accidents

- totally rebuilding engines and transmissions for vehicles that have done over 800,000-900,000 km

- programming the destination signs so they display custom messages like “Go Canucks Go”

- constructing almost all the body parts for conventional buses in the fleet

- warehouse storage and inventory control for all vehicle parts

- and even more, if you can believe that

(I should mention that Fleet Overhaul only takes care of articulated and conventional buses—community shuttle repairs are done elsewhere.)

I was really lucky to go on a tour of the facility a few weeks ago, so in this series, I’ll share lots of behind-the-scenes photos and video to let you see just what they do there.

We’ll start with the body shop!

Fleet Overhaul’s body shop

Here’s a video looking at the body shop floor at Fleet Overhaul. The panel fabrication area is in the foreground, and the buses up on the hoists are in the back, of course. (That’s overhaul manager Jeff Dow speaking in the video, by the way.)

You can’t see it that clearly in the video above, but there’s another row of service bays further back. In total, there are 10 service bays on the body shop floor, four spots for vehicles in the adjoining paint shop, and two more spots for vehicles in the aisles.

Here’s another video showing the body shop service bays from the ground level:

The body shop takes up just part of the large Fleet Overhaul building, but Jeff explained that this centre is actually too small for the size of our fleet.

A new maintenance facility is planned to open in Maple Ridge in 2012, doubling the space to about 230,000 square feet.

Fleet Overhaul moved to this building in 1986 – it was originally a Kenworth facility, where large trucks were built in the 1950s. Fleet Overhaul was initially located out at Cambie Garage at Cambie and 16th in Vancouver.

Mid-life overhauls

About 50 buses come through the body shop for rebuilds every year. As I’ve touched on, mid-life overhauls are one of the major reason buses come into Fleet Overhaul.

Basically, when buses reach eight to 10 years of age, Fleet Overhaul takes the vehicle in to do a mid-life overhaul, restoring the bus to basically new condition so that it can serve another eight to 10 years in the system.

Body, paint, and trim manager Jack McKenna explained that in Canada, buses tend last 17-18 years due to the mid-life overhauls that Canadian agencies perform on buses. In the U.S., vehicles last 12 years – instead of doing major mid-life overhauls, they tend to just buy new vehicles.

What happens in a mid-life overhaul? The vehicle is stripped down to its chassis and the body is reinforced and repaired. Flooring and lower body panels are replaced; rust is removed and rustproofing put on and seats reupholstered if needed.

It takes about five weeks to fully overhaul a conventional 40’ bus, and about 50 buses are overhauled every year. About 12 articulated buses are overhauled each year – articulated buses take about two months for a full overhaul, and as well, there’s only a few specialized lifts that can hoist the longer 60’ artics in the air.

Here’s a few more pictures of the articulated bus in the midst of its overhaul.

Major vehicle repairs

Another key reason buses come to Fleet Overhaul is for major repair work.

Jeff explained that while every outlying transit centre has a body and paint person to fix minor bus scrapes, major work like accident repairs are done at Fleet Overhaul.

For example, at left you can see a new Nova bus that has been rear-ended on the left side, now being repaired. This Nova was hit during the snowstorm over Christmas 2008—that snowstorm in fact tripled the volume of repair work for Fleet Overhaul.

(Rear-ending on the left side is apparently a common major vehicle repair – as body, paint, and trim manager Jack McKenna explained, that’s the side of the bus exposed to traffic as it pulls out of a stop.)

Side note: Jack said that the new Nova buses have a stainless steel frame that won’t rust, and other plastic body elements, meaning that the buses requires shorter mid-life overhauls to keep them in long-time service.

Here’s some more photos of bus repairs at Fleet Overhaul.

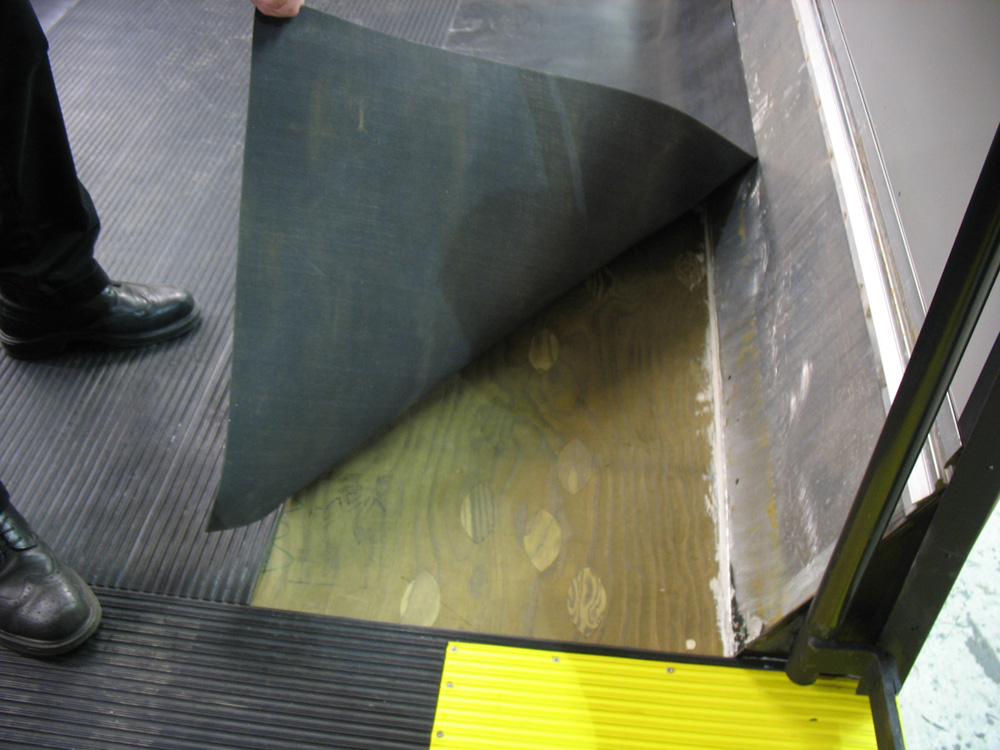

Plywood floors!

Also, here’s something very interesting I learned about the buses while at Fleet Overhaul: the buses have plywood panels under the rubber matting!

Fleet Overhaul has a carpentry shop across the street that provides the plywood floors. Plywood is in fact the industry standard, so basically any bus you travel on in North America has plywood panels as its flooring structure.

And Jack McKenna said that the buses ordered in 2009 are the first to have composite, non-plywood flooring.

Whew – so that is it for the body shop area of Fleet Overhaul! Watch out for part two in the near future, where we’ll talk about panel fabrication (a.k.a. how we make all of the body panels for vehicles on site)!

hey jen!

man wat a treat for me i’ve always wanted to see what its like at the the fleet overhaul center! i have some questions:

1) what do they do if for example and articulated bus’s bellow (rubber cover that covers around the walkway of the turning joint) gets like a big cut in it?

2) do the buses have to park in they’re assinged spot or in a line?

3) what is the cycle a bus does on its route?

Hi Daniel, glad you liked the article!

Can I just clarify questions 2 and 3 with you so I can get the right answers?

2) For bus parking — are you referring to where they park at a depot, or where they park in the body shop service bays?

If it’s a depot, they do have assigned spots, or at least spots that are tracked by staff. That’s because the next morning, when operators start their shifts, they are told where their vehicles are parked in the lot — if the vehicle isn’t there, that’s a problem!

3) I’m not certain what you mean by “cycle” when you ask “What is the cycle a bus does on its route?” Do you mean how far it travels, or something else?

Hi Jhenifer:

I Have Remembered That The 27, 28, 99, 130, 134, 135, 136, 144, 110, 112, 123, 129, 106,

129, 125 Operate Out Of The Burnaby Transit Centre On Kitchener Street East Of Boundary Road.

I Also Took The 28 To & From Joyce Station

When I Was A Customer For TansLink In 1989 Until 2001 & Was Very Good With The System

& Reading The Time Of Every Bus Schedules.

A great article. Can’t Help but notice that the 2 MVA’s are both brand new buses.

I would like to know what happens to buses with the engines that catch fire? I heard sometimes they rebuild and then again they do not. Is there anyway to clarify that?

A very interesting read. Regards to the B-line in the first pic (B8006), in addition to the standard maintainence, does that include a change in the appearance, paint-wise? like for example using the current paint livery for the new trolleys?

Wow, so that’s where all the buses magically become all new again! Is there a reason why the Nova buses have a different livery than the New Flyer buses (where the top is light grey rather than dark grey)? Also, do some of the newer New Flyer trolleys and diesels have a yellow swoosh that doesn’t appear to thin out at the front?

dear jen,

for question #2 you’ve answered it but for question 3 i meant like for wxample a 28 joyce station bus arrives at joyce, after unloading, what does the driver do?

Very cool. And, what an impressive facility and crew. I guess I knew buses would need repair and such, but I didn’t really stop to think that we’d have a single facility like this. They make parts from scratch too? That building looks like an airplane hangar!

Looking at the pictures of the articulating joint…. I was wondering what people’s opinions about what should go in the joints.

On some artics the joints have 4 seats, some have 2 single seats facing one another, and finally on others there are no seats, but 2 large pads to lean on. Do riders have a preference? Perhaps this would be a future friday poll question. What’s the logic behind what goes in there?

I’m not a big fan of having seating in that section. It’s narrow enough and slows people trying to get to the back of the bus when you have 4 people sitting in there, especially with long legs. A compromise could be a double seat on one side and the large lean pads on another.

Dave:

The engines catch fire? I don’t know about that specifically, but Fleet Overhaul does have a mechanical shop devoted to rebuilding engines and transmissions — I’ve got a post later on talking about that in specific. There are have tools to analyze engine parts and see what is salvageable or not, and can also totally rebuild engines that have any damage or wear from long-term use.

Jhenifer,

I know of a t least 5 coaches in the last 6 months that have caught on fire or have had some sort of fire on board. And it really is a high number for a 6 month period. P3353, B7395, B803?, and 2 brand new nova buses. Also with the overhall pic showing B8006 its funny that i was on the exact bus on the 135 it was b/o for mechanical problems then sent right back out on the road 2 hrs later on the same run. never fixed! And that actually happens far too often. You may disagree with me on this but if you ride some of the PoCo coaches regularly you will notice it. Cause there was one coach that had around 14 water leaks in the roof. I think it was B8016 i can;t remember. All i know the bus was b/o on the 135 and put right back in service on the 99 B-Line for the PM Rush in the pooring rain. This is another issue that MUST be looked into.

Thanks Jhenifer I look forward to that posting!

Cree:

I asked Jack about whether they repaint buses to new colour scheme after a mid-life overhaul, and he said no: the new metallic paints are very expensive, and as we’re only going to get another half life out of the bus, the extra expense isn’t worth it.

Daniel J:

I asked Jack about your question too, and it turns out Nova buses are not actually painted!

I’ll just quote him exactly here:

As for the yellow swoosh, Jack says he’s been to the Flyer factory several times, and as far as he knows, they have always used the same paint template. But he says he’ll have a look at some of the buses and give us an update later on.

hey jen just one more question,

are u going to be making a series on skytrain’s operations and maintanence center?

Daniel: I’m looking into it. We’ll see :)

Daniel:

In answer to question 3 —

If it’s the last trip of the night, then the bus goes back to the yard (generally not in revenue

service) and it has various operations take place, such as emptying of fare box, maintenance issues noted to mechanics, washing etc.

If it’s the end of its scheduled trip, the bus has recovery, which is to put it back onto its scheduled time. This means the bus can sit

for minutes, or move to another location if it is going into service on another route (which is part of interlining). This time is also used by

the operator to stretch his/her legs, use the washroom etc.

I was wondering what did they do with bus #2147 after it was vandalized in 2007? I noticed that it was in the fleet overhaul centre!

Hi Dave, I’ve asked about 2147 and Jack McKenna says this: “The bus is tucked away in a corner at Vancouver Transit Center. It is getting repaired by both Electricians and Bodymen.”

Wow. Thanks for sharing this, Jhenifer. It’s interesting.

I wouldn’t have guessed wood floors.

Where are community shuttle repairs done?

Where are the trolley buses repaired? As far as I know, there are only trolley wires in Vancouver. Since fleet overhaul is done in Burnaby, are the trollies towed to Burnaby transit center for fleet overhaul, then towed back to Vancouver transit center after the service work is complete?

Ric, here is the answer from our fleet management department.

If fleet overhaul takes care of major repairs and the transit centers takes care of minor repairs as well as repairs for the Community Shuttles, there is on thing that I found strange when I saw it and put this question in my mind. Just this past Thursday I went by the GM dealership on Marine Drive in Vancouver and saw a Community Shuttle in the repair shop at the GM dealership.

What was the Community Shuttle doing at GM’s repair shop?

Should the repairs have been done at OTC instead?

Ric: here is the answer from fleet management.

On night August 24, 2010, a plane crashed in Heilongjiang province in northeast china, caused 42 dead and 52 injured.Deep mourn to those people!

Hi Jen, I was wondering how come some buses from depots do not operate on their “appropriate” routes. For e.g, I recently saw P8096 doing the 135, a burnaby route.