PHOTOS: Behind the scenes printing decals for mandatory masks

PHOTOS: Behind the scenes printing decals for mandatory masks

TransLink’s service area spans more than 1,800 square kilometres, which makes it the largest in Canada by far! What does that mean? It means more than 8,300 bus stops across the region and more than 1,600 buses in our fleet.

The small but mighty sign shop at Coast Mountain Bus Company looks after fabricating and installing signs for all these bus stops, as well as creating the decals for all the buses.

What are some of the decals they create? It runs the gamut! It includes the fleet numbers (the single letter and four-to-five digit number you find on the front, back and sides of buses like B18001 or V2101), “Fare Paid Zone,” no smoking, the “Thanks for the brake” bumper sticker and so much more.

With masks mandatory onboard transit, it means new and updated decals and signs across the transit system. In total, we’re installing more than 8,000 signs:

- 2,300 signs installed on the bus system

- 2,350 signs installed on SkyTrain and Canada Line

- 2,315 interior ads on vehicles

- 700 signs installed on HandyDART vehicles

- 418 signs installed on Compass faregates

It’s a herculean task for our sign shop that looks after bus portion. Thousands of decals have to be printed, cut to size and shape, delivered to six different bus depots across the region and finally installed on all buses in less than two weeks.

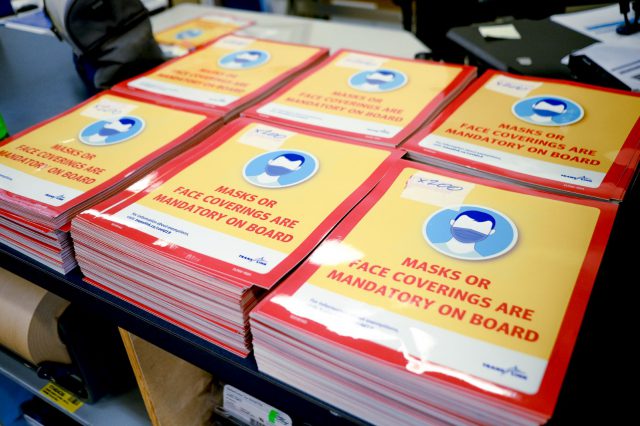

The first decal is a simple “Masks or Face Coverings are Mandatory Onboard” decal that will go on the window near the front door to remind customers as they board the bus.

The second decal is an updated rules and regulations posted on the partition behind the bus operator. These are being printed on a low-tac (removable) vinyl. It will go on top of the existing rules and regulations, so that once the pandemic is over they can be easily removed.

Printing at the sign shop isn’t like printing at home. Each kind of decal we print is unique in its size and shape, so it’s not as simple as loading the correct size paper and running your printer all day unattended. The decals have to be printed on a large, 54-inch wide vinyl sheets, then cut to size and shape. It’s also a jigsaw puzzle to fit the maximum number of decals onto each sheet to minimize waste.

At home, a fast, colour laser printer might be able to print about 3,000, 8.5-by-11 pages in just half an hour. That’s not the case for our specialized sign shop printers. The print heads move across millimetre by millimetre, laying down the ink and prints about a foot every 30 minutes.

Not only is printing a meticulous and detailed process, the printing has to happen in sections of about 10 feet because if we print one large, giant roll, it would get heavy and stick to itself. After one section is done, the printed sheet is cut from the roll and reset to print the next section.

Once printed, the vinyl sheets have to dry, which takes about 12 hours, before they can be applied to surfaces. In the case of the “mandatory masks” decals, they also have to be laminated since it’s being applied to the exterior of the bus and will be exposed to the elements.

Once that’s all done, the process begins to cut the large sheets into individual decals. The transit rules and regulations, and mandatory masks decals are two different sizes and shapes, so they’re cut separately.

Stacks of 200 decals are created for delivery to bus depots in Vancouver, Port Coquitlam, Richmond (two locations), Burnaby and Surrey to be installed onboard more than 1,600 buses in total.

The big reveal will be on Monday, August 24 when masks become mandatory. The sign shop has started delivering the decals to the bus depots and installation is underway.

How are old decals disposed? Are they recyclable?