How we’re connecting SkyTrain to the new maintenance centre, explained

How we’re connecting SkyTrain to the new maintenance centre, explained

The SkyTrain network is expanding thanks to funding unlocked through past 10-Year Investment Plans. We’re adding more than 200 new Mark V cars to the network and extensions to the Expo and Millennium Lines are set to open before the end of the decade.

It’s a race against the clock to ensure the network is ready to welcome the new cars and extensions. We’re also in a sprint to secure an injection of new funding to continue to expand the transit system and meet the needs of an ever-growing population in Metro Vancouver.

Among the myriad projects that we need to complete is the opening of a new operations and maintenance centre near Braid Station so there’s additional space for storing and maintaining our growing SkyTrain fleet.

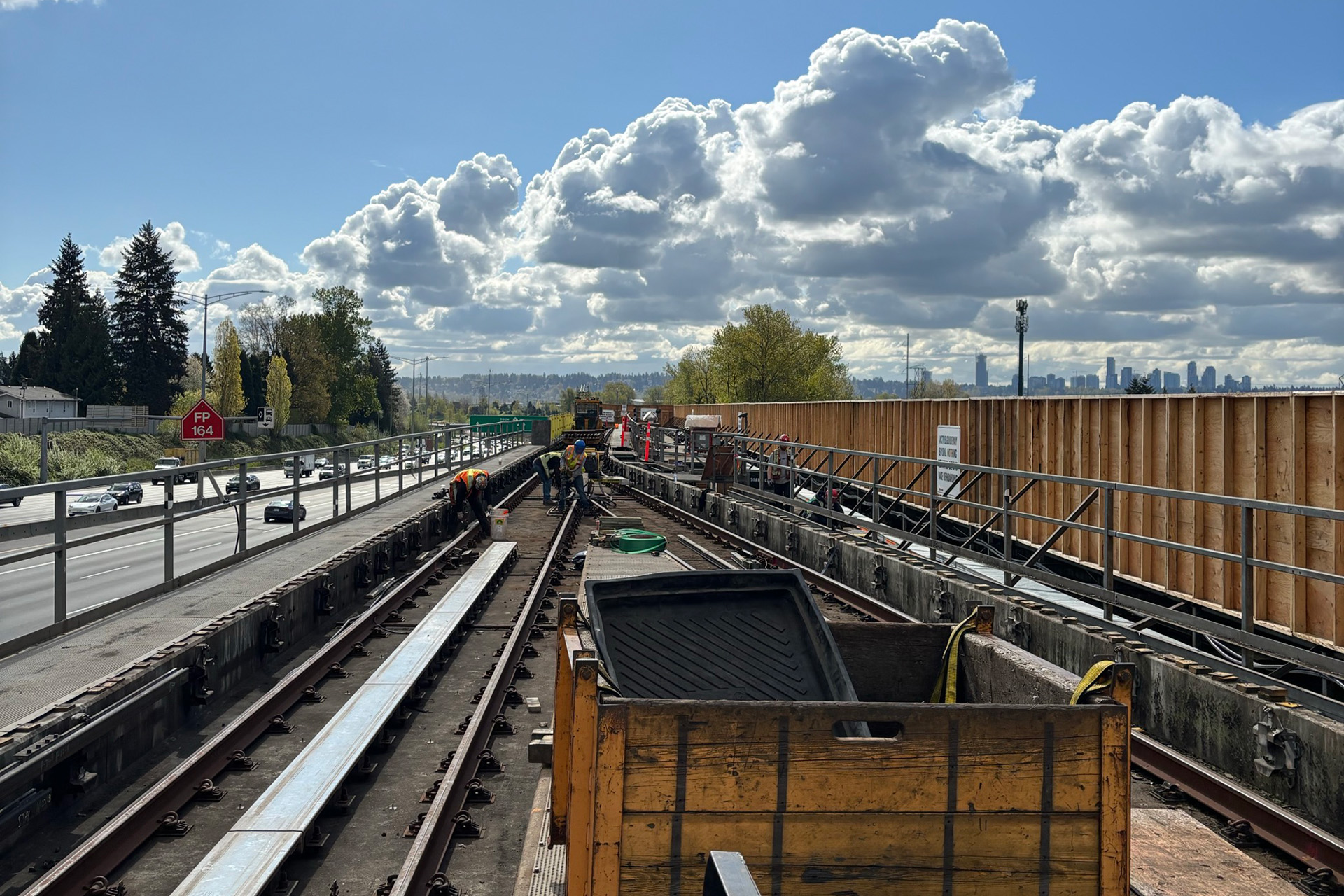

The centre will connect to the SkyTrain network at the tracks parallel to the Trans-Canada Highway, between Braid and Lougheed Town Centre station. Construction crews are building this connection until early 2026.

That’s why there are changes to Expo Line service between Sapperton and Production Way–University stations, including reduced service between Lougheed Town Centre and Production Way–University. This is so we can close one side of the tracks for construction while trains continue to operate on the other side.

Trains to and from Lougheed Town Centre and Production Way–University are running every 12 minutes all day instead of every 6-10 minutes to accommodate this single tracking (i.e., trains are using the same tracks in both directions).

A herculean task

This connection to the operations and maintenance centre is going to take about two years to complete.

It’s one of the most ambitious projects we’ve ever undertaken.

We’re completely rebuilding the tracks in a constrained area — all while continuing to operate trains.

Have you ever tried to do renovations in your home while still living in it? It’s like that. Things just take a little bit longer and are a little bit more complicated.

Now imagine you are renovating your bathroom. It’s straightforward if you are doing a replacement. Simply remove the old bathtub and put a new one back in the same location. Easy peasy lemon squeezy.

But it becomes a herculean task if you want to move it to another part of the bathroom. You need to start relocating pipes and electrical, which will necessitate cutting into the floor and walls among other things.

That’s essentially what we are doing to the tracks near Braid Station — we are moving our bathtub around in the bathroom because it doesn’t work for us anymore where it is located.

We need to rebuild the tracks so they can service the new operations and maintenance centre that will be located directly southeast of the tracks. As you can expect, when that area was built, it wasn’t built with an operations and maintenance centre in mind.

What we’re doing

We are building two new track switches and changing the direction of the pocket track in the area. Track switches allow trains to move from one track to another, while a pocket track is like a parking lane that’s used for repositioning and storing trains.

The new track switches will allow trains to move from the tracks of the new operations and maintenance centre to the Expo Line tracks. Simply put, it makes it possible for trains to enter and exit the operations and maintenance centre.

Because the connection to the operations and maintenance centre is at the outbound track, the direction for entering and leaving the pocket track needs to be changed so trains can directly access the pocket track from the operations and maintenance centre tracks to enter service in the inbound track.

The inbound track refers to the tracks for trains travelling from Braid to Lougheed Town Centre Station, while the outbound track refers to the tracks for travel from Lougheed Town Centre to Braid Station. The pocket track is where we stage trains for entering and exiting service.

Without the change in direction for the pocket track, trains would have to first travel in the wrong direction on the outbound track to enter the pocket track to travel back in the other direction to enter service on the inbound track. Essentially, the train would have to inefficiently travel in a “Z” pattern to enter service on the inbound track and it would delay regular train service on the outbound track.

By changing the direction of the pocket track, we eliminate this inefficient pattern for trains entering service. The train can take a simpler diagonal, “\” pattern instead.

Careful deconstruction of multiple systems equipment

When you look at the SkyTrain tracks, there’s so much more than simply the tracks the trains run on, which we call the running rail.

There’s also the power rail (also called the third rail) that supplies electricity to the trains. There’s the reaction rail, which is the metal plate (i.e., linear induction motor) that’s between the two running rails, that allows the train to move forwards and backwards.

That’s just the rails.

There’s also myriad pieces of equipment that enable train operations. All have to be decommissioned, protected during construction, reinstalled, and re-commissioned.

This includes cables and components for communications, power, and automatic train controls connected to the rails that communicate with and make the train stop and go.

There are switch machines that use hydraulics to physically push a track into position so trains can switch tracks. At the same time, propulsion power transfer switches ensure continuous power for the trains when they switch tracks.

There are blue light indicators that show if the tracks are powered on and electrified. This is a critical safety feature for staff who work on the tracks.

Additionally, there are power centres that convert the 600-volt power the SkyTrain uses into 120 volts, which is the same voltage as what you find at home. This provides power to myriad pieces of equipment such as lights, telephones, and heaters to ensure our switch machines don’t freeze during the winter months.

We’re also constrained by the Trans-Canada Highway on one side, and the BNSF and Canadian National railroad tracks on the other side.

As a result, this isn’t a demolition but rather a careful deconstruction where pieces are documented and moved off site to be reinstalled later.

This complicated and needed work is why we’re so thankful for your patience while we complete this important work over the next two years so the SkyTrain network can grow and continue to serve our region.